What Are the Benefits and Applications of CNC EDM Medium-Speed Wire Cutting Machines in Precision Manufacturing?

2025.01.10

2025.01.10

Industry news

Industry news

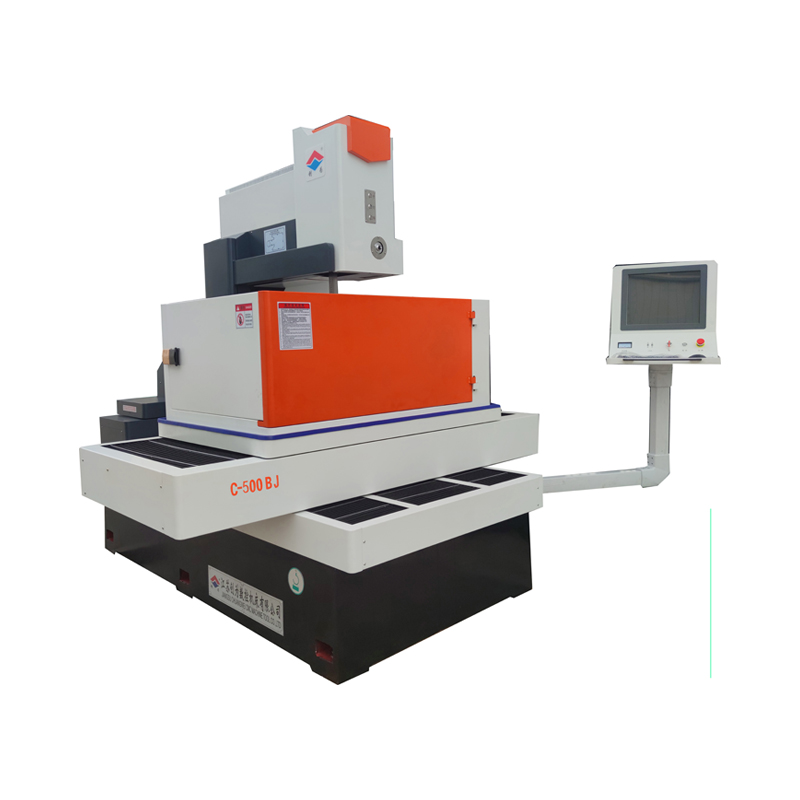

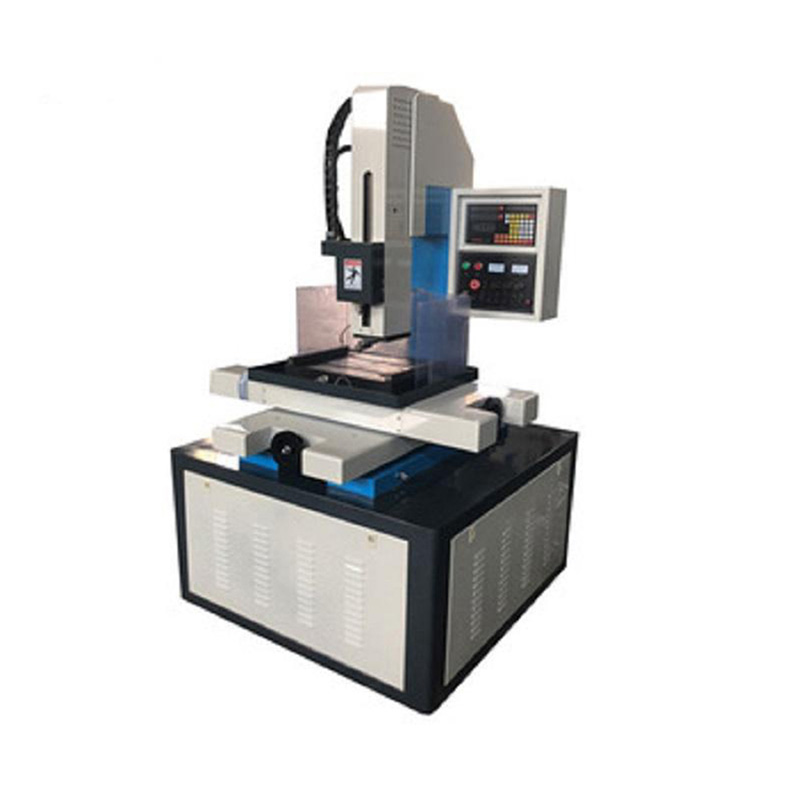

In the ever-evolving landscape of modern manufacturing, precision and efficiency have become the cornerstone of success. One technology that has gained significant traction in industries ranging from aerospace to automotive is the CNC EDM (Electrical Discharge Machining) medium-speed wire cutting machine. This advanced equipment plays a pivotal role in the manufacturing of intricate, high-precision parts that would otherwise be impossible to achieve using traditional machining methods.

One of the standout features of the CNC EDM medium-speed wire cutting machine is its unparalleled precision. The wire cutting process enables manufacturers to achieve incredibly tight tolerances, often reaching sub-micron levels. This makes it suitable for the production of parts such as molds, dies, and intricate components in the aerospace, automotive, and electronics industries.

The wire cutting process is not limited to straight cuts; it can handle highly complex shapes and contours with ease. The CNC control allows the wire to follow intricate paths, enabling the production of highly detailed and custom-designed parts that are difficult or even impossible to achieve with conventional machining methods.

Since the cutting process relies on controlled electrical discharges rather than physical contact, there is minimal heat generated. This significantly reduces the risk of material deformation, making it ideal for cutting delicate or hard materials without causing warping or distortion.

While CNC EDM machines are known for their precision, the medium-speed wire cutting machine provides a cost-effective solution for small batch production. It strikes a balance between speed and cost, allowing manufacturers to produce parts efficiently without incurring the high costs associated with high-speed wire cutting machines.

CNC EDM wire cutting machines are compatible with a wide range of materials, including hardened steels, titanium alloys, copper, and even some ceramics. This versatility makes them indispensable in industries where a variety of materials need to be processed to tight specifications.

One of the most prominent applications of CNC EDM medium-speed wire cutting machines is in mold and die making. The ability to cut complex, detailed shapes with tight tolerances makes these machines ideal for creating molds used in plastic injection molding, die-casting, and stamping. Manufacturers in the automotive, medical, and electronics industries rely on this technology to produce precision molds and dies that can withstand high volumes of production.

In the aerospace and defense sectors, where the highest level of precision is critical, CNC EDM medium-speed wire cutting machines are used to manufacture intricate components such as turbine blades, landing gear components, and other mission-critical parts. The ability to work with high-strength alloys and complex geometries ensures that these parts meet the rigorous performance standards required in these industries.

The medical device industry also benefits from the capabilities of CNC EDM wire cutting machines. From surgical tools to implants, the need for precise, high-quality components is paramount. Wire cutting machines can create small, complex features that are essential in medical devices, ensuring both their functionality and safety.

Another critical use of CNC EDM medium-speed wire cutting machines is in prototyping. Designers and engineers can quickly create prototypes for testing, enabling them to evaluate the form and function of a part before moving into full-scale production. The precision of the wire cutting process ensures that prototypes match the final product closely, reducing the need for rework and costly design changes.

The CNC EDM medium-speed wire cutting machine represents a significant leap forward in precision manufacturing, providing industries with the tools needed to produce complex, high-quality components efficiently and cost-effectively. With its ability to cut intricate shapes, work with a variety of materials, and deliver exceptional precision, this technology is poised to remain at the forefront of the manufacturing sector for years to come. As industries continue to demand greater accuracy and innovation, CNC EDM medium-speed wire cutting machines will play a key role in meeting these needs.

English

English Español

Español