With point-to-point automatic assisted positioning, positioning function, with automatic mould leaning and centre point finding function, providing more quick mould calibration ability;

Mechanical home position is automatically zeroed, when power failure occurs in the middle of machining, the computer will automatically find the mechanical home position;

With round O-square mouth, cross, cross, hexagonal and quadrilateral single-section machining function, can do swing machining, side discharge machining;

Provide 5 groups of oscillating function settings, the same group of moulds have 30 groups of Z-axis different depth conditions setting function;

DRY RUN" can be simulated before discharge machining to test the correctness of programming;

Reverse cross-cycle machining can be adopted for multi-hole machining, which makes the effect of depth of each hole machining more even;

Dialogue type Chinese and English operation screen, processing can be input according to the user's habit, simple keyboard, easy to learn and understand;

Continuous processing of up to 100 holes (fixed holes can be repeated for 4000 times processing).

High-sensitivity infrared detection fire prevention system with automatic power cut-off function;

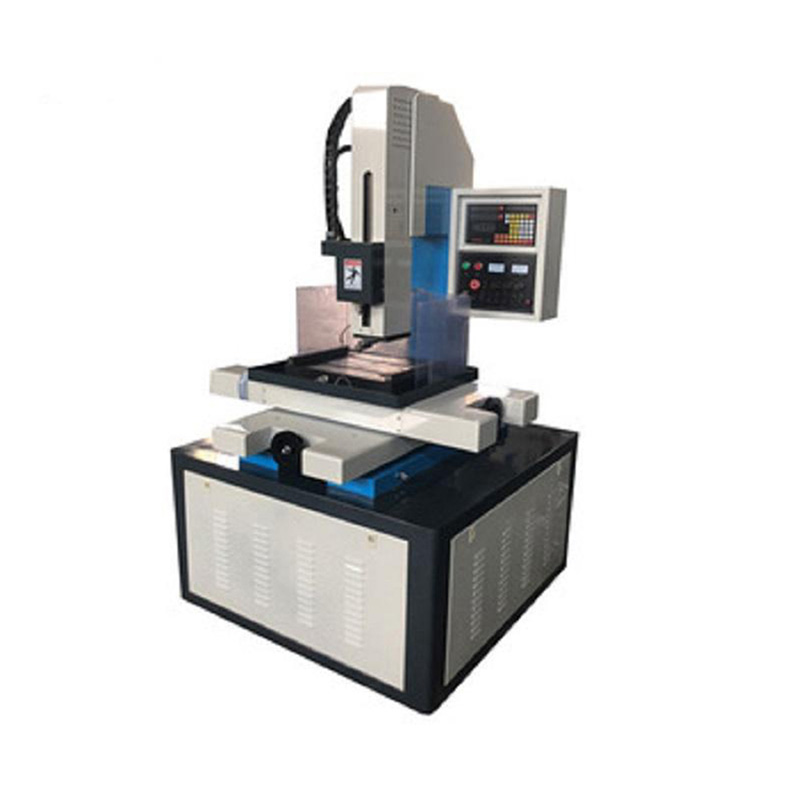

Adopt high-grade Meehanna cast iron, excellent material, good rigidity, and high stability;

With ten sections of automatic repair function, can be rough - medium - fine one time to complete the processing;

Can:

A, self-editing, according to human experience to edit the processing conditions;

B, AUTOZ automatic editing, given a large amount of depth of the initial current, and the completion of the coarse and fine selection, will automatically edit the processing conditions;

C. Intelligent conditions editing, as long as the choice of electrode shape, electrode and workpiece material, electrode cross-sectional area and processing completion of the choice of thickness and depth settings will automatically edit the processing conditions;

Provide 60 groups of file storage, you can store 60 different moulds or customer information;

Carbon deposit prevention automatic adjustment and automatic slag discharge function;

Mirror plus circuit can really etch out the mirror effect;

Three-axis optical ruler monitoring function, to ensure the shift precision, can be converted to metric and imperial;

Full-featured discharge function selection, easy to understand the operation panel, mechanical status at a glance;

The newly designed power supply conforms to European CE safety specifications, which is dustproof, waterproof, anti-interference, and improves the life of the electronic version;

The use of industrial-grade PC-BASE controller and DOM memory: DC, DERVO, DRIVER, over-current, over-speed, overload, and short-circuit protection.

Low electrode consumption rate, strong function suitable for many different materials discharge processing.

Slideway device linear slide, smooth travel, the use of ball screw, Fu move light.

The working table surface is not easy to be damaged by the high-frequency treatment and grinding surface.

The slideway adopts a V-type and plane design and uses a TURCITE-B wear-resistant sheet with heavy pressure to slide down lightly and with high precision.

With copper to copper, copper to steel, graphite to steel, steel to steel, copper to aluminium, graphite to aluminium, graphite to steel, copper to tungsten steel (powder metallurgy) processing functions.

English

English Español

Español