How Does the High-Speed GZ CNC EDM Wire Cutting Machine Achieve Taper Cutting?

2025.01.17

2025.01.17

Industry news

Industry news

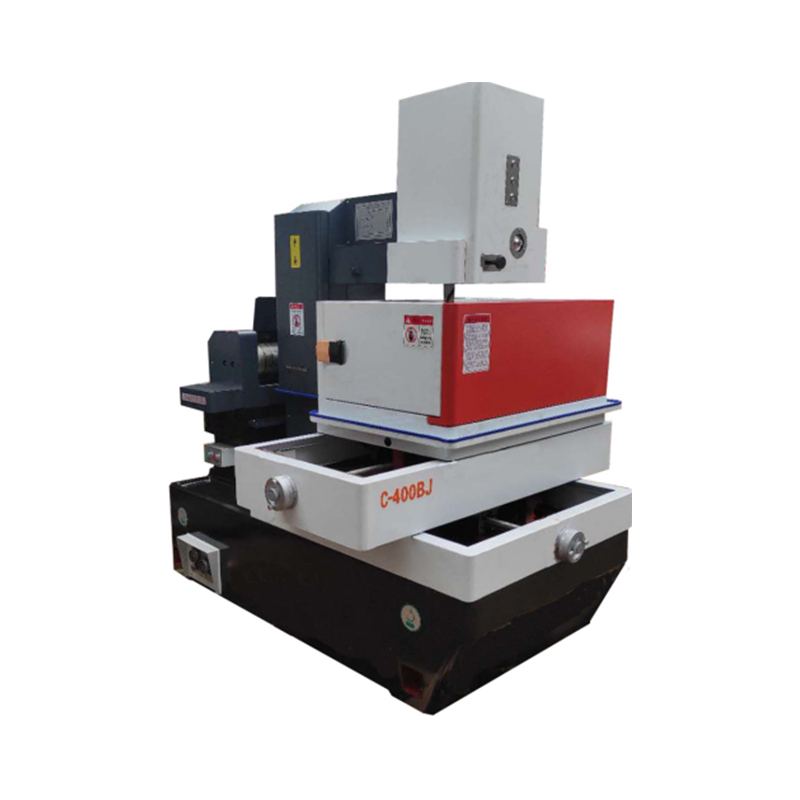

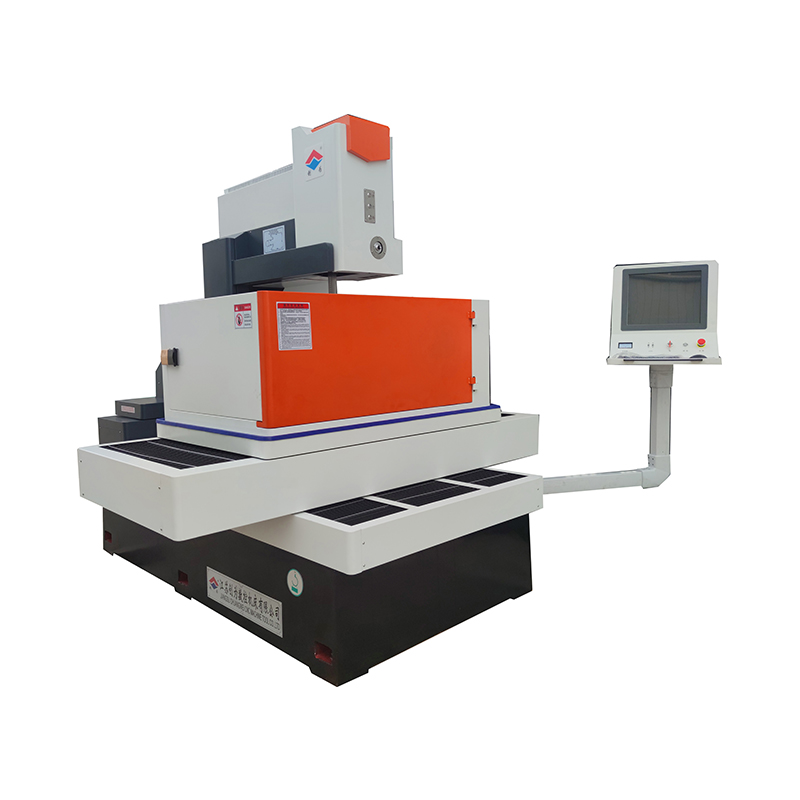

Taper cutting is a sophisticated manufacturing process that requires precision, consistency, and innovative engineering. Among the industry-leading technologies, the high-speed GZ CNC EDM wire cutting machine stands as a paragon of excellence. Its ability to achieve complex taper cuts with remarkable accuracy sets it apart from conventional wire cutting machines.

Taper cutting involves slicing a workpiece with a varying cross-sectional angle, which requires the cutting tool to move along non-parallel paths. This process is commonly used in applications where precise angles or beveled edges are critical, such as in aerospace, automotive, and medical device manufacturing. Achieving these intricate geometries demands advanced technology and meticulous control mechanisms, both of which are integral to the GZ CNC EDM wire cutting machine.

The Role of Advanced CNC Technology

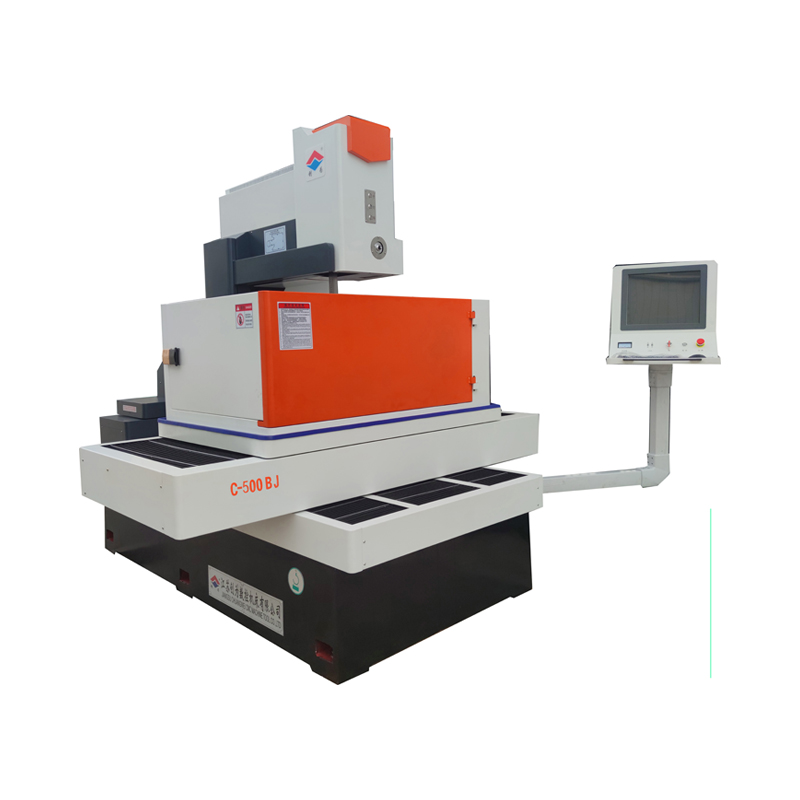

The high-speed GZ CNC EDM wire cutting machine integrates cutting-edge computer numerical control (CNC) technology, which serves as the brain behind its precision. This sophisticated system ensures:

Dynamic Wire Control: The CNC system adjusts the wire's tension and speed in real-time, allowing for consistent performance during complex cutting paths.

Multi-Axis Coordination: The machine can maneuver the wire along multiple axes simultaneously, enabling intricate taper angles that are difficult to achieve with traditional methods.

Error Compensation: Real-time feedback mechanisms correct deviations, ensuring that the final product adheres to exact specifications.

Key Features That Enable Taper Cutting

1. High-Precision Wire Movement

The GZ CNC EDM machine employs servo-controlled wire guides that allow for micron-level adjustments. These guides ensure that the wire maintains its intended path, even when executing sharp or intricate taper angles. The result is a flawless cut that meets even the most stringent design requirements.

2. Adjustable Wire Inclination

One of the standout features of this machine is its ability to tilt the wire at precise angles relative to the workpiece. This inclination is achieved through an advanced tilting mechanism, which works in tandem with the CNC system to deliver unparalleled accuracy in taper cutting.

3. Integrated Dielectric Systems

The machine's dielectric system plays a crucial role in maintaining cutting stability. By flushing dielectric fluid at controlled rates, it minimizes heat accumulation and ensures a consistent cutting environment, which is vital for achieving smooth taper angles.

Benefits of the GZ CNC EDM Wire Cutting Machine

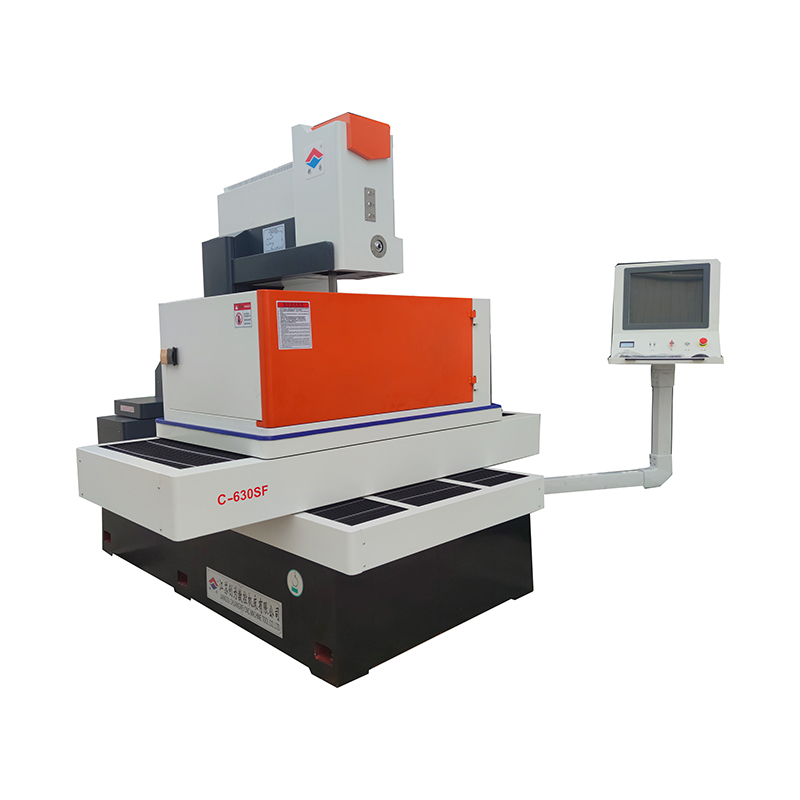

1. Enhanced Efficiency

The high-speed capabilities of the GZ machine significantly reduce cutting times without compromising precision. Manufacturers can achieve faster turnaround times, making it an ideal choice for high-demand industries.

2. Superior Surface Finish

Thanks to its advanced control systems and optimized cutting paths, the machine produces exceptional surface finishes, reducing the need for additional post-processing.

3. Versatility

From intricate medical components to robust aerospace parts, the GZ CNC EDM wire cutting machine handles a wide range of materials and applications, making it a versatile asset in any manufacturing setup.

The high-speed GZ CNC EDM wire cutting machine is a technological marvel that redefines the capabilities of taper cutting. By combining advanced CNC technology, precise wire control, and innovative engineering, it delivers unparalleled accuracy and efficiency. For industries that demand perfection in every cut, this machine is not just an option—it is a necessity.

English

English Español

Español