How does the DK77 CNC Wire EDM FZ handle multiple cuts?

2024.09.09

2024.09.09

Industry news

Industry news

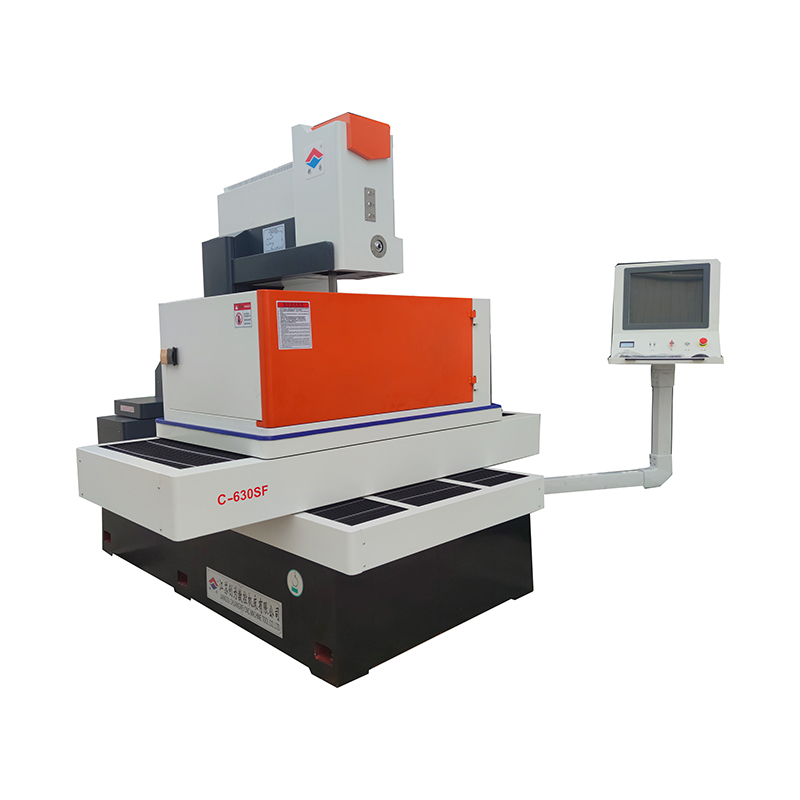

The DK77 CNC Wire EDM (Electrical Discharge Machining) FZ machine is designed to handle multiple cuts effectively, leveraging advanced CNC control systems and optimized wire path strategies. Multiple cuts, also known as multi-pass cutting, are a key feature in EDM machining used to achieve higher precision, better surface finishes, and tighter tolerances. Here's how the DK77 CNC Wire EDM FZ manages multiple cuts:

Multi-Pass Cutting Strategy:Roughing and Finishing Cuts: The DK77 CNC Wire EDM FZ typically performs multiple cuts in a sequence that includes one or more roughing cuts followed by several finishing cuts. The roughing cut is designed to remove the bulk of the material quickly, while subsequent finishing cuts refine the surface quality and achieve the desired accuracy.Programmable Cutting Parameters: The CNC system allows operators to program different parameters for each pass, including cutting speed, power settings, and wire tension. This ensures that each pass is optimized for its specific purpose—removing material efficiently or refining the finish and accuracy.

Adaptive Control Features:Real-Time Adjustments: The DK77 machine is equipped with an adaptive control system that can adjust parameters in real-time based on the cutting conditions. This helps maintain stability and precision throughout multiple passes by compensating for changes in material thickness, hardness, or other variations.Constant Spark Gap Control: The machine's control system monitors the spark gap during cutting to ensure consistent machining conditions. By maintaining a constant spark gap, the DK77 can provide more accurate cuts and minimize the risk of wire breakage, especially in finishing passes.

Wire Path Optimization:Optimized Wire Path Programming: The CNC software of the DK77 machine allows for precise control of the wire path to minimize unnecessary movements and ensure efficient multi-pass cutting. The optimized wire path reduces the total machining time and enhances the surface finish by eliminating overcut or undercut issues.Automatic Reverse Cutting: For improved accuracy and surface quality, the machine may incorporate an automatic reverse cutting feature where the wire EDM machine moves back along the same path for finishing cuts, enhancing precision by smoothing out any deviations from the initial cut.

Wire Management and Control:Automatic Wire Threading (AWT): The DK77 CNC Wire EDM FZ often comes equipped with an automatic wire threading system, which facilitates seamless operation during multi-pass cutting. The AWT system can automatically re-thread the wire after a break or when moving between cuts, reducing downtime and ensuring continuous operation.Wire Tension Control: The machine maintains optimal wire tension throughout the multiple cuts, preventing wire deflection and ensuring high accuracy in tight tolerance applications. Proper tension control is crucial during finishing passes to achieve a smooth and precise cut.

Machining Speed and Quality Balance:Adjustable Cutting Speed: The DK77 machine's CNC controller allows for adjustments in cutting speed based on the type of cut being performed. Roughing cuts are generally faster with higher power settings, while finishing cuts use slower speeds and lower power to achieve a better surface finish.Enhanced Surface Quality: By utilizing multiple cuts, the machine can achieve excellent surface finishes, often down to Ra 0.2–0.8 µm, depending on the material and cutting conditions. The number of finishing passes can be adjusted based on the required surface quality.

Process Automation and Control:Pre-Programmed Cutting Cycles: The DK77 CNC Wire EDM FZ can store and recall multiple pre-programmed cutting cycles, allowing for easy setup of multi-pass cutting operations. This feature is particularly useful for repetitive or batch production scenarios where consistent quality is required.Remote Monitoring and Adjustment: For enhanced process control, the machine may offer remote monitoring capabilities, allowing operators to adjust cutting parameters on-the-fly during multi-pass operations to optimize performance or address unforeseen issues.

Thermal Control and Stability:Thermal Management Systems: The DK77 machine uses dielectric fluid to control the temperature during the EDM process, which is crucial for maintaining dimensional accuracy during multiple cuts. The fluid also helps to flush away debris, preventing overheating and ensuring consistent cutting conditions.Minimization of Workpiece Deformation: By carefully controlling the amount of material removed in each pass and maintaining stable thermal conditions, the machine minimizes the risk of thermal deformation, ensuring higher precision and reducing the need for secondary operations.

User-Friendly Interface and Programming:Intuitive CNC Interface: The user interface of the DK77 machine is designed to be user-friendly, allowing operators to easily set up and manage multiple cutting passes. Operators can input specific parameters for each pass and customize the sequence based on the desired output.

Simulation and Preview Capabilities: Before executing multi-pass cuts, the DK77 CNC Wire EDM FZ may offer simulation and preview functions to help visualize the cutting path, check for potential collisions, and optimize the process for time and accuracy.

Support for Complex Geometries:Capability for Tapered and Complex Cuts: The DK77 CNC Wire EDM machine can handle complex geometries and tapered cuts by precisely controlling the wire path and the angle of the wire during multiple passes. This capability is beneficial for applications requiring intricate and precise shapes.

Impact on Tooling and Maintenance:Tooling Wear Management: Multiple cuts reduce tooling wear by distributing the material removal workload more evenly across several passes, extending the life of consumables like wires and guides.Maintenance Requirements: Regular maintenance, such as cleaning filters and replacing worn parts, is essential for maintaining the performance of the DK77 machine during multi-pass operations. Proper maintenance ensures consistent precision and reduces the risk of machine downtime.

The DK77 CNC Wire EDM Machine FZ effectively handles multiple cuts through its advanced CNC control system, adaptive cutting strategies, optimized wire path programming, and robust thermal management.By leveraging these features, the machine can achieve high precision, excellent surface finishes, and efficient material removal in various applications, making it suitable for industries such as aerospace, medical, automotive, and tool and die manufacturing.

English

English Español

Español