How does Electrical Discharge Machining (EDM) work in wire cutting?

2024.08.13

2024.08.13

Industry news

Industry news

Electrical Discharge Machining (EDM) is a sophisticated manufacturing process that excels in creating precise and intricate shapes from a variety of materials, making it invaluable in precision engineering. At the heart of EDM wire cutting is the principle of controlled electrical discharges, which enables the machine to cut through metals with high accuracy and minimal mechanical stress.

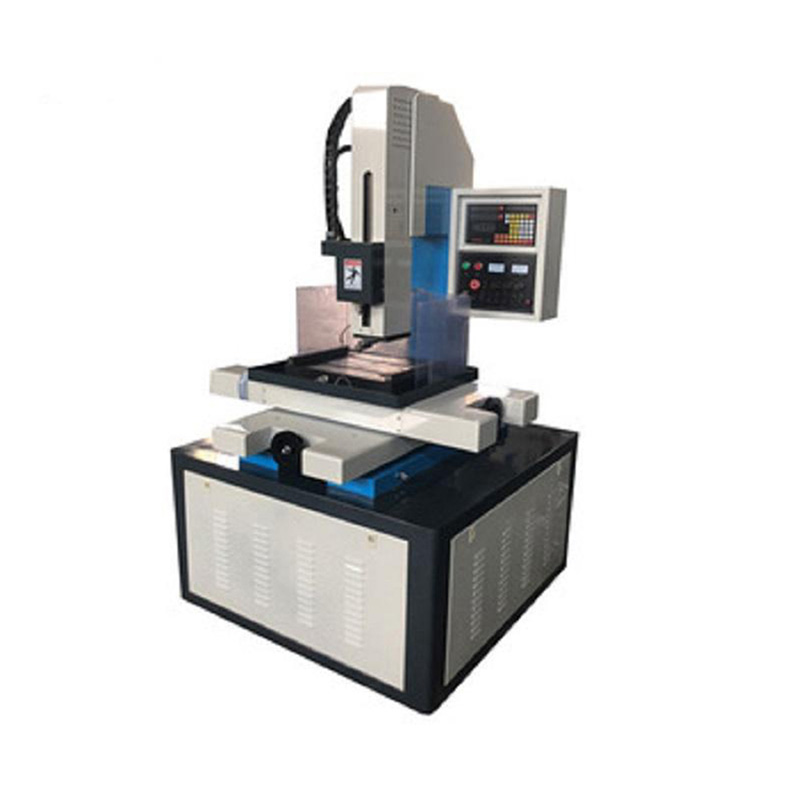

In a CNC EDM High Speed Wire Cutting Machine, the cutting process begins with a thin, tensioned wire, which acts as the electrode. This wire is electrically charged and is held in close proximity to the workpiece, which is also electrically charged but grounded. When the wire and workpiece are brought together, a series of rapid, high-frequency electrical discharges occur across a small gap between them. These discharges generate localized heat intense enough to melt and vaporize the material in the workpiece, effectively eroding it away. The process happens in a controlled manner, allowing for the creation of complex and detailed shapes without direct mechanical contact between the wire and the workpiece.

One of the standout features of the CNC EDM High Speed Wire Cutting Machine is its advanced operational efficiency. The high-speed servo motors and automatic wire threading mechanisms significantly enhance the speed and reliability of the cutting process. This automation reduces setup times and minimizes operator intervention, making it ideal for high-volume production environments. The precision of the machine ensures that intricate designs and tight tolerances can be achieved consistently, which is crucial in industries such as aerospace, automotive, and electronics.

Moreover, the CNC (Computer Numerical Control) aspect of the machine allows for highly sophisticated programming and control. This capability ensures that complex geometries and intricate patterns are executed with exceptional accuracy, providing a significant advantage over traditional machining methods. The machine’s robust construction and high-quality components contribute to its durability and reliability, even under demanding conditions.

The use of EDM wire cutting is particularly advantageous when working with hard and difficult-to-machine materials, such as titanium and hardened steel. These materials, often challenging for conventional cutting tools, are handled with ease by the EDM process due to its non-contact nature, which avoids issues like tool wear and deformation. The efficiency of EDM wire cutting not only enhances the quality of the finished parts but also reduces material waste and lead time, leading to cost savings and improved productivity in manufacturing operations.

Electrical Discharge Machining (EDM) wire cutting leverages a precise and controlled electrical discharge process to achieve high-quality results in material cutting. The CNC EDM High Speed Wire Cutting Machine enhances this process with automation and advanced control features, offering a powerful tool for producing intricate and detailed components efficiently. Its ability to handle challenging materials and maintain high precision makes it an indispensable asset in modern precision engineering.

English

English Español

Español