What types of materials can CNC EDM high speed wire cutting machine effectively cut?

2024.08.13

2024.08.13

Industry news

Industry news

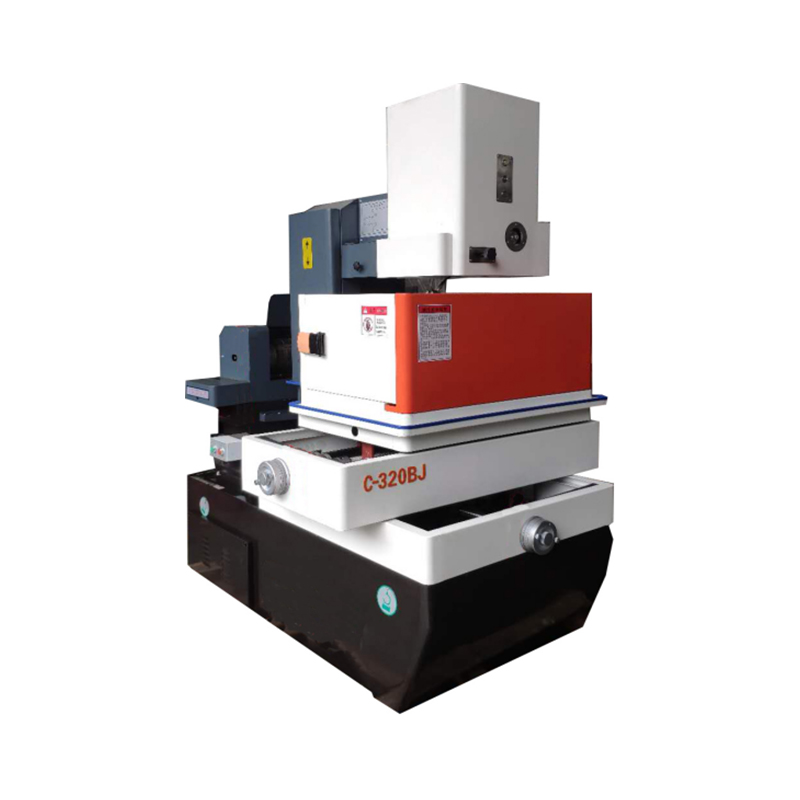

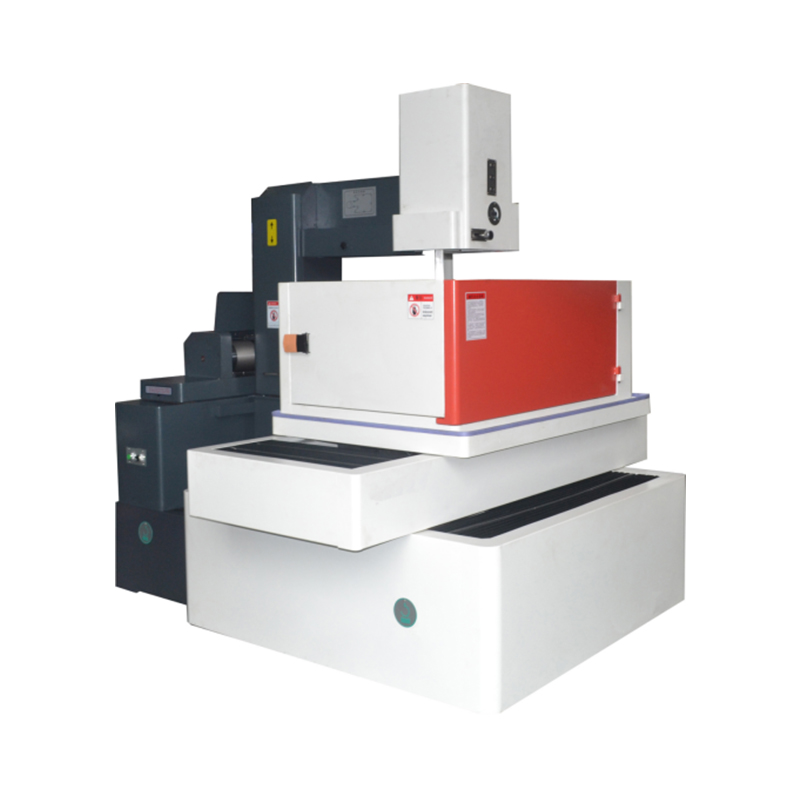

CNC EDM high speed wire cutting machines are versatile and can effectively cut a wide range of conductive materials. Some of the most common materials that these machines can process include:

Steels: All types of steels, including tool steel, stainless steel, high-speed steel, and hardened steel.

Aluminum alloys: Various grades of aluminum alloys can be cut with high precision.

Titanium alloys: Titanium and its alloys, which are known for their high strength-to-weight ratio and corrosion resistance, can be easily cut using EDM wire cutting machines.

Copper and copper alloys: Pure copper and its alloys, such as brass and bronze, can be efficiently cut.

Tungsten carbide: Despite its hardness, tungsten carbide can be accurately machined using EDM wire cutting technology.

Graphite: Graphite, often used in molding and tooling applications, can be precisely cut with these machines.

Inconel and other superalloys: High-performance alloys like Inconel, Hastelloy, and Monel, which are difficult to machine using conventional methods, can be cut effectively with EDM wire cutting machines.

Conductive ceramics: Some conductive ceramic materials, such as silicon carbide and zirconia, can be machined using this technology.

Polycrystalline diamond (PCD): PCD, known for its extreme hardness, can be cut and shaped using EDM wire cutting machines.

The ability to cut such a wide range of materials makes CNC EDM high speed wire cutting machines an essential tool in various industries, including aerospace, automotive, medical, and electronics manufacturing. However, it's important to note that the specific machine's capabilities and the optimal cutting parameters may vary depending on the material being processed and the desired outcome.

English

English Español

Español