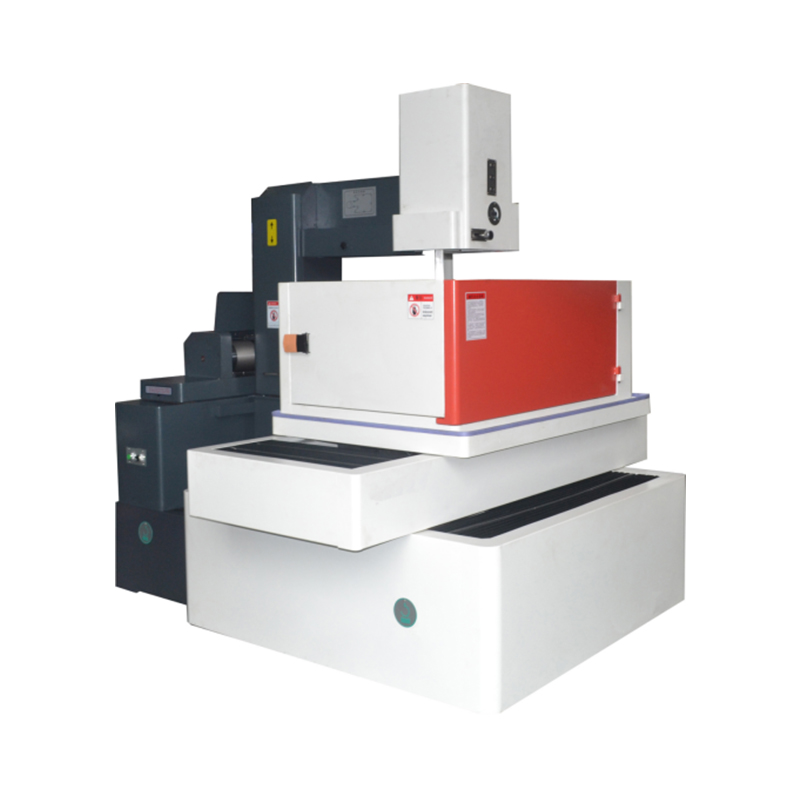

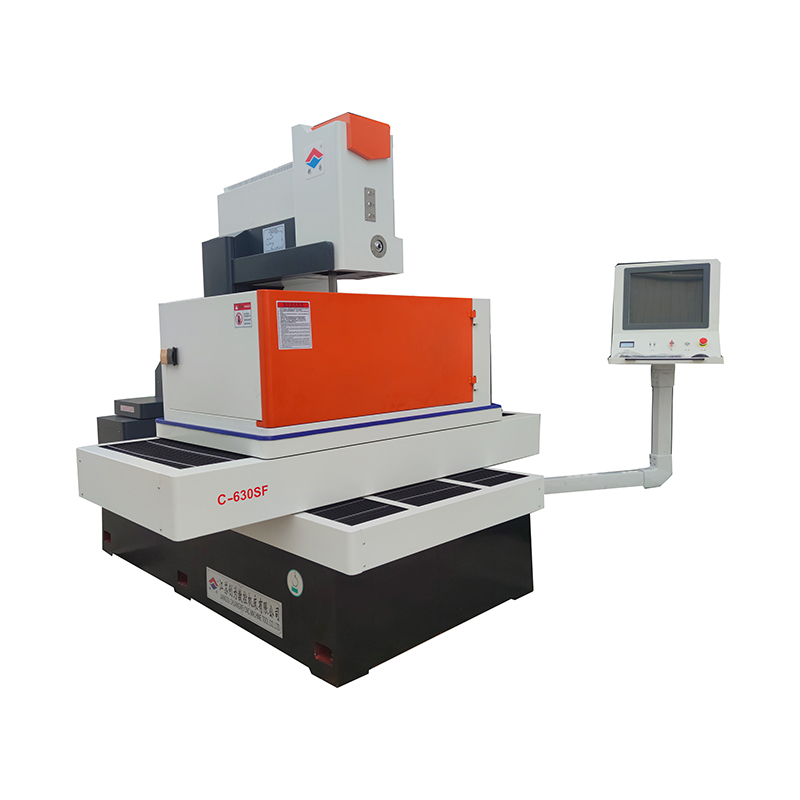

EDM HOLE DRILLING MACHINE Equipment Maintenance and Care How to choose tools and materials for cleaning work?

2024.08.13

2024.08.13

Industry news

Industry news

When choosing tools and materials for cleaning work, EDM Hole Drilling Machine needs to comprehensively consider the material, structure, use environment and specific requirements of the machine tool. Here are some suggestions:

Soft cloth or dust-free cloth: used to wipe the surface of the machine tool, especially the control panel, display and other vulnerable areas to avoid scratches.

Used to remove dust and debris inside the machine tool, especially the hard-to-reach corners and gaps. The vacuum cleaner should be industrial-grade to ensure strong suction and will not damage the surface of the machine tool. The compressed air gun should pay attention to controlling the air pressure to avoid blowing away dust or damaging precision parts.

Choose a suitable brush according to the shape and material of the machine tool surface, such as a soft brush, electrostatic brush, etc., to remove stubborn stains and grease.

For specific cleaning tasks, such as cleaning coolant tanks, filters, etc., professional cleaning tools and equipment may be required, such as high-pressure cleaners, ultrasonic cleaners, etc.

Cleaners that are non-corrosive and non-damaging to the machine tool material should be selected. For metal surfaces, neutral detergents or special metal cleaning agents can be used; for electrical components and control systems, detergents containing water should be avoided to prevent short circuits or damage.

During the cleaning process, lubricating oil may be needed to lubricate certain parts, such as guide rails, lead screws, etc. Products compatible with the original lubricating oil of the machine tool should be selected, and their cleanliness and viscosity should be ensured to meet the requirements.

After cleaning, for parts or areas that need to be kept dry, desiccant can be used for drying to prevent rust or mildew.

Before cleaning, be sure to cut off the power supply of the machine tool and follow the safety operating procedures to prevent electric shock or other safety accidents.

According to the different parts and materials of the machine tool, select appropriate cleaning tools and materials for classified cleaning to avoid cross contamination or damage.

During the cleaning process, water or other liquids should be avoided from splashing into the interior of the machine tool, especially the electrical system and lubrication system.

After cleaning, ensure that all parts of the machine tool are dry to prevent rust or short circuits caused by moisture.

When choosing tools and materials for EDM Hole Drilling Machine cleaning work, multiple factors need to be considered comprehensively to ensure the cleaning effect without damaging the machine tool. When choosing tools and materials, you should refer to the machine tool's manual and maintenance guide, or consult a professional machine tool maintenance personnel.

English

English Español

Español