Can medium wire cutting meet the processing requirements of the modern electronics industry?

2024.12.19

2024.12.19

Industry news

Industry news

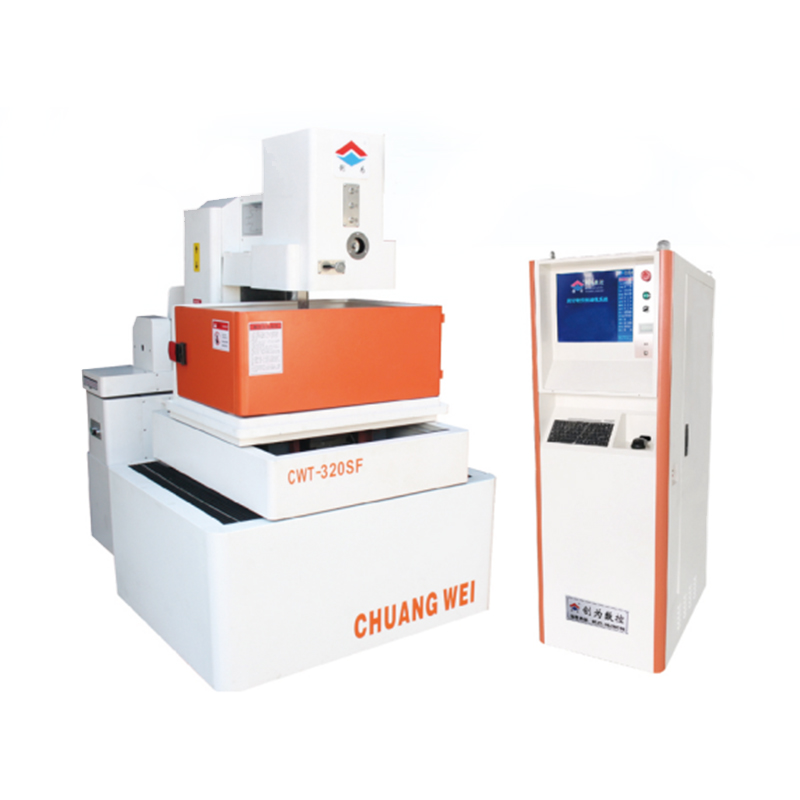

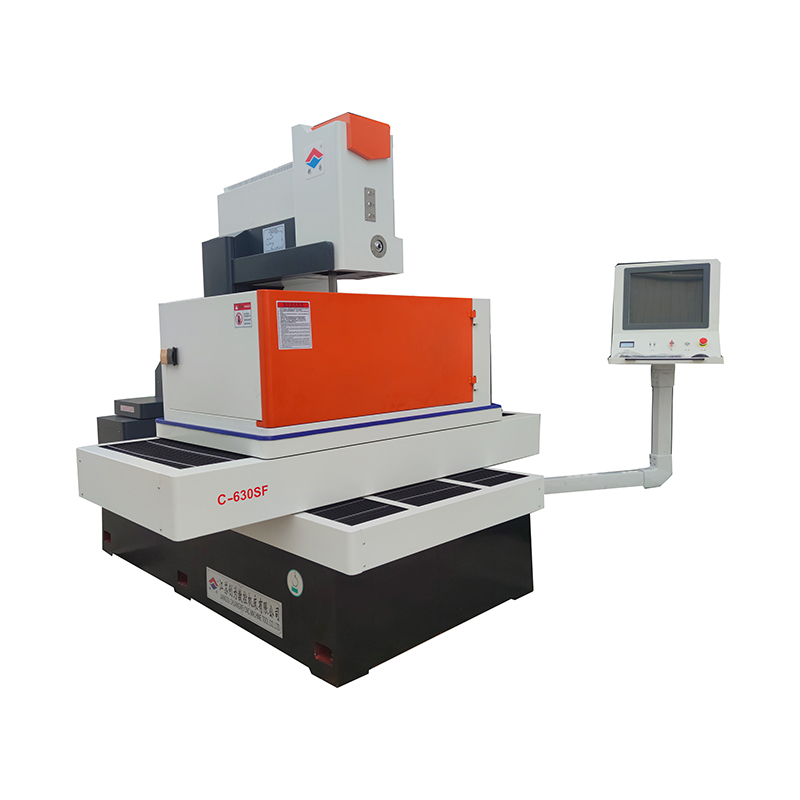

In modern manufacturing, precision machining technology plays a vital role. Medium wire cutting as a precision EDM technology, has been widely used in mold manufacturing, automobiles, aerospace, electronics and other fields. It can efficiently process metal parts of complex shapes, especially for metal materials with high hardness or good conductivity.

Medium wire cutting is a processing method for precision cutting of metal materials by the principle of electric spark discharge. The basic principle is to use a thin metal wire (usually copper or molybdenum wire) as an electrode, generate heat through high-frequency discharge, melt or vaporize the metal on the surface of the workpiece, and complete the cutting. Unlike traditional machining, medium wire cutting does not rely on the tool to directly contact the workpiece, but completes the processing through the current discharge between the electric spark and the workpiece, so it can handle materials with extremely high hardness.

The medium wire cutting machine uses a thin electrode wire (usually 0.1mm to 0.3mm copper wire or molybdenum wire) and applies electric pulses to the workpiece through high-frequency current to achieve layer-by-layer cutting of metal. During the cutting process, the gap between the electrode wire and the workpiece is very small, and the workpiece surface is gradually melted and removed through high-frequency discharge.

During the processing, the cutting area is continuously cooled by coolant (usually deionized water or oil) to keep the temperature of the electrode wire and the workpiece surface under control. Due to the local heating characteristics of the electric spark, medium-sized wire cutting can cut in a very fine way, even metals with higher hardness, such as high-strength steel and titanium alloys, can be processed smoothly.

Medium-sized wire cutting technology is widely used in many fields, especially in the manufacture of high-precision parts and molds.

The manufacture of molds usually requires extremely high precision, especially in the case of complex shapes or narrow holes. Medium-sized wire cutting can accurately cut complex geometric shapes without damaging the surface of the workpiece, which is an ideal choice for the mold industry.

In the automotive and aerospace industries, many parts need to have high precision and strong hardness. For example, engine parts, aircraft structural parts, etc. The processing of these high-strength materials requires not only high precision but also good surface quality. Medium-sized wire cutting can meet these needs, especially in the processing of complex structures and large-sized parts.

Among electronic components, the cutting of some complex circuit boards and the punching of micro holes can all be completed by medium-sized wire cutting technology. It can accurately control the cutting position and ensure the electrical performance of the product.

Many high-precision mechanical parts, such as precision gears, bearings, and cutters, need to be processed by medium-sized wire cutting. Its high precision and stability enable it to meet the precision requirements of these fields.

With the advancement of science and technology, medium-sized wire cutting technology continues to develop in the direction of higher precision, higher efficiency, and more environmental protection. The following are several important development trends:

In the future, medium-sized wire cutting equipment will become more and more precise and can achieve micron-level processing accuracy. At the same time, the application of new control systems and software will make the processing process more efficient and reduce processing time.

With the development of artificial intelligence and robotics, more and more medium-sized wire cutting equipment will integrate automation and intelligent functions. This not only improves the automation level of processing, but also reduces the errors and risks caused by human operation.

In the context of increasingly stringent environmental regulations, future medium-sized wire cutting technology will pay more attention to reducing energy consumption and waste emissions. The use of environmentally friendly coolants and the reduction of noise and vibration during processing will become the direction of future development.

As a precision machining method, medium-sized wire cutting technology has been widely used in mold manufacturing, automobiles, aerospace, electronics and other industries. With its advantages of high precision, high efficiency and ability to process high-hardness materials, medium-sized wire cutting technology has an irreplaceable and important position in modern manufacturing. With the continuous innovation of technology, medium-sized wire cutting in the future will be more sophisticated, efficient and environmentally friendly, promoting the continuous development of manufacturing processes in all walks of life.

English

English Español

Español