What are the measurements of a centre-wire machine?

2024.07.02

2024.07.02

Company News

Company News

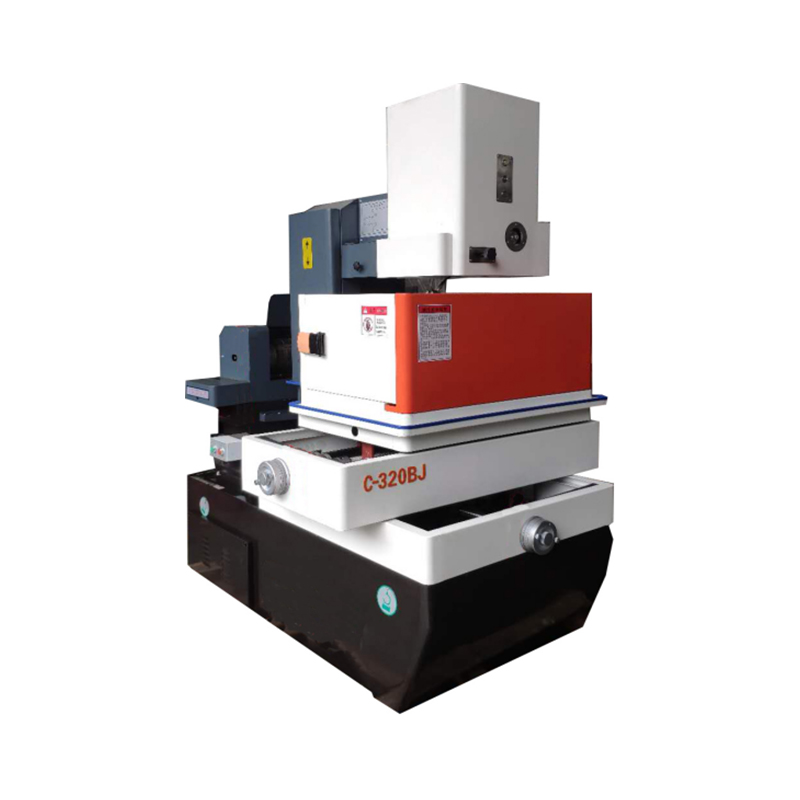

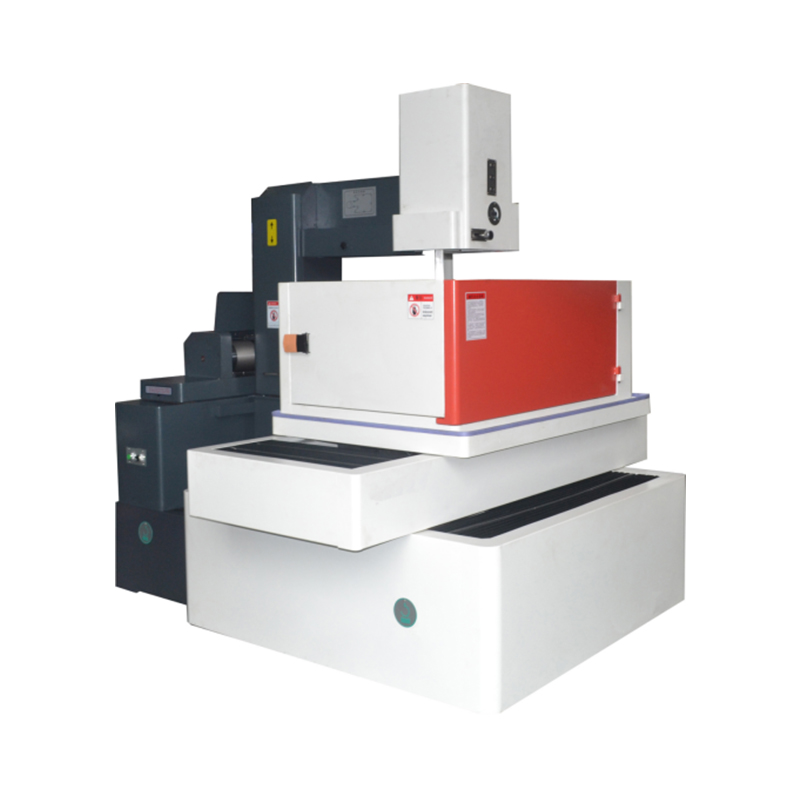

How can I choose high-precision medium-sized wire-cutting machine tools? Nowadays, with the rapid development of technology, the major machine tools all over the market, the quality also varies, so how can you choose the many machine tools in high-quality

High-precision products? From the following six points easily selected high-precision CNC machine tools.

Point: precision

Walking wire machine tools are different from other mechanical products, there is no precision in the walking wire in a pile of scrap metal, the key technical indicators are the quantitative embodiment of the advanced technology of machine tools, reference to the required parameters of the machine tool is to ensure the accuracy of the basic conditions.

The key technical index is the quantitative embodiment of the advanced technology of the machine tool.

The second point: is cutting time

Cutting time in the walking wire machine tool continuous cutting time, cutting efficiency if you can not continuously process, then the processing efficiency is no practical value, so the continuous and stable cutting time in the walking wire directly affects the

So the continuous and stable cutting time of the wire walker has a direct impact on the choice of the machine tool.

The third point: is roughness

Walking wire machine tools to ensure that the premise of precision should also ensure that the roughness of the machine tool, Sanno mechanical roughness of the surface of the walking wire: RAs0.8um

Fourth point: stability

In a dozen or even dozens of the same parts of the batch of continuous machining, or continuous machining of jump step die size consistency is particularly important; Note! The continuous processing referred to here means that no

The continuous machining referred to here means that the operator is not allowed to artificially check and compensate for the diameter of the molybdenum wire.

Point 5: Cutting taper

High-precision wire-cutting machine tools in the large cutting taper of 6-12 °, the surface roughness can still be maintained in the RA ≤ 0.8um, which is more valuable.

Sixth point: intelligent operation

The processing quality of the medium-wire cutting machine tool is good, if it must rely on the personal skills of the operator to achieve, such a machine tool can only be a low-end product, SANNO high-precision medium-wire cutting machine tool, the use of human

SANNO's high-precision medium wire-cutting machine adopts a humanized operation mode to provide processing conditions.

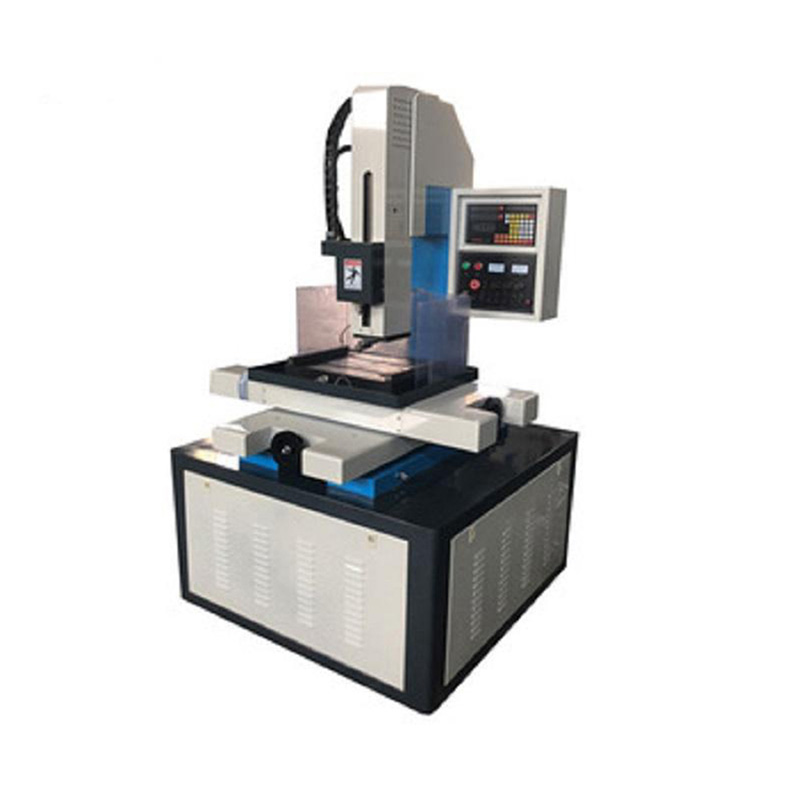

Then how it be regarded as the regular operation of the wire? Because often wire-cutting machine problems, manufacturers say that it is caused by improper operation, but do not give the standardized operation steps of the wire. Today Tongfang

Control machine tools to share with you the formal operation steps of the wire walking.

1, regularly check the wire walking machine line, whether the electronic components are loose. If there is any abnormality, immediately carry out maintenance.

2, on the molybdenum wire before checking the guide wheel, discharge wheel, and conductive block are working properly. If there is a problem, replace it immediately.

3, on the molybdenum wire, check the molybdenum wire tension. And whether the water flow is normal.

4, will be in the wire-cutting motor lock, check in the locked state of the table can be pushed by hand.

5、Drawing and programming.

6, in order to ensure the smooth operation of the molybdenum wire walking machine tools, water flow is normal in the case of the start of processing.

7, when all the processing is over, need to shut down the machine, you should first close all the procedures, and then through the beginning of the function to open and close the computer. Wait until the computer is completely shut down, before cutting off the power supply.

English

English Español

Español