How does the C-type stepper CNC wire EDM medium-speed cutting machine affect the cutting process and overall performance?

2024.10.08

2024.10.08

Industry news

Industry news

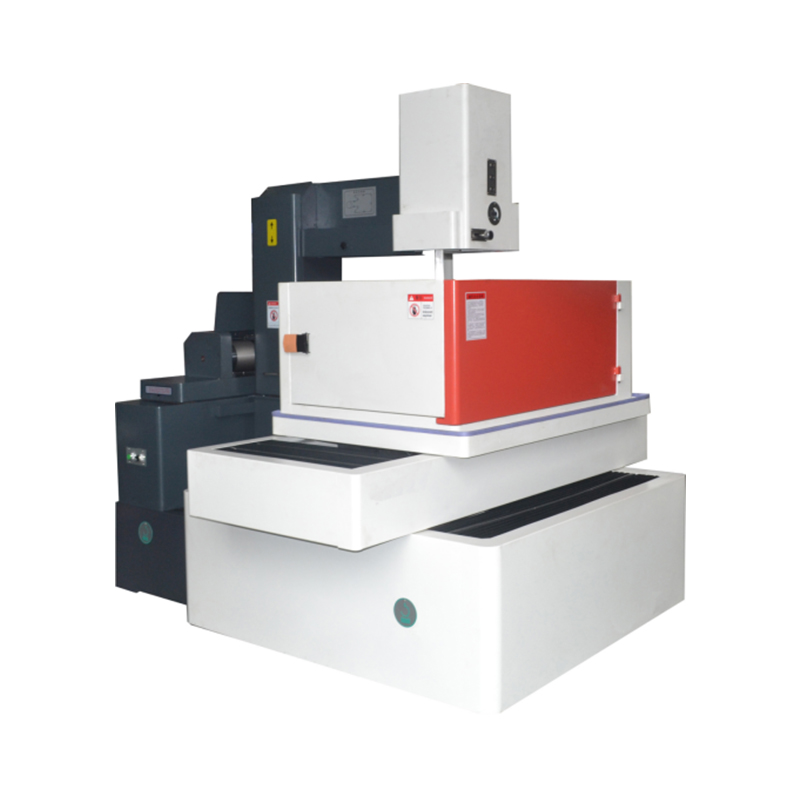

The C-type stepper CNC wire EDM (Electrical Discharge Machining) medium-speed cutting machine can significantly affect the cutting process and overall performance in several ways:

Precision and Accuracy: The stepper motor system provides high precision in positioning, enabling the machine to produce intricate shapes and fine details with tight tolerances. This is crucial for industries requiring exact specifications.Cutting Speed: While classified as a medium-speed machine, it can effectively balance speed and quality. The machine is designed to optimize cutting speeds for different materials, enhancing efficiency without compromising the finish.

Wire Tension Control: The C-type design often allows for better wire tension control, which is critical for maintaining cutting accuracy and reducing wire breakage. Proper tension ensures consistent performance throughout the cutting process.Cooling System: An efficient cooling system is essential for preventing thermal distortion during the cutting process. The EDM machine typically uses a dielectric fluid to cool both the workpiece and the wire, which helps maintain dimensional accuracy.

Surface Finish: The quality of the surface finish is influenced by the machine's design and operational parameters. C-type stepper machines can produce smooth surfaces, minimizing the need for secondary finishing processes.Material Versatility: These machines can effectively cut a wide range of materials, including hard metals, alloys, and composites. This versatility allows manufacturers to use them for diverse applications, enhancing productivity.

Complex Geometry Handling: The CNC control system enables the machine to execute complex geometries and intricate designs. This capability is particularly beneficial in applications like mold making, aerospace components, and automotive parts.Reduced Setup Time: Modern CNC systems often come with advanced programming capabilities, allowing for quick changes in setup. This feature minimizes downtime between jobs and increases overall throughput.

Automation and Workflow Integration: The ability to integrate with automated systems and workflows enhances operational efficiency. The machine can be part of a larger production line, reducing manual intervention and streamlining processes.

Reliability and Maintenance: The design and components of the C-type stepper CNC wire EDM machine can contribute to its reliability. Proper maintenance protocols can extend the machine's lifespan and ensure consistent performance over time.Cost Efficiency: By optimizing cutting processes and minimizing waste, the machine can contribute to overall cost savings in production. This efficiency can improve the return on investment (ROI) for businesses using the machine.

The C-type stepper CNC wire EDM medium-speed cutting machine enhances cutting performance through precision, speed, material versatility, and advanced control systems, making it a valuable asset in various manufacturing environments.

English

English Español

Español