What are the daily maintenance requirements for the DK77 CNC Wire EDM FZ?

2024.08.13

2024.08.13

Industry news

Industry news

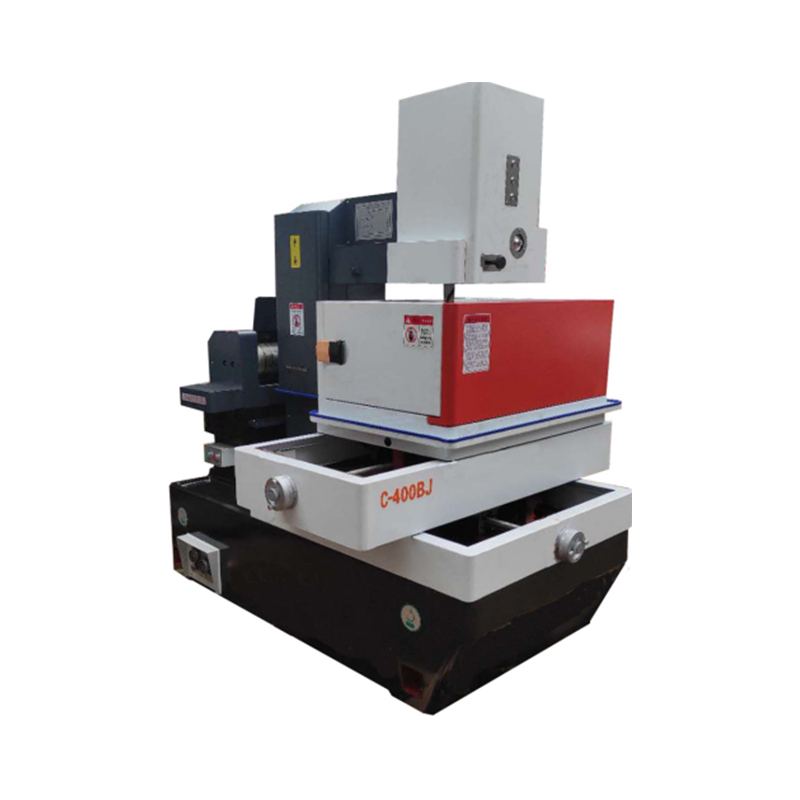

Daily maintenance for the DK77 CNC Wire EDM Machine FZ is essential to ensure smooth operation, prevent downtime, and extend the machine's lifespan. Here are the key daily maintenance tasks typically required:

Check Dielectric,Fluid LevelsAction: Inspect the dielectric fluid reservoir to ensure it is at the correct level.Purpose: Adequate dielectric fluid levels are crucial for cooling, flushing, and electrical discharge.

Inspect Fluid,QualityAction: Check the dielectric fluid for contamination or degradation.Purpose: Contaminated fluid can affect machining quality and performance.

Clean the Work Area,Action: Remove debris, dust, and metal chips from the machine and work area.Purpose: Prevents contamination of the machine and ensures a clean working environment.

Examine the Wire Feed System,Action: Check the wire feed unit for proper operation and ensure that the wire spool is correctly mounted.Purpose: Proper wire feed is critical for consistent machining performance.

Inspect Electrodes and Workpieces,Action: Examine the condition of electrodes and workpieces for wear or damage.Purpose: Ensures that the components are in good condition for accurate machining.

Check Electrical Connections,Action: Inspect electrical connections and cables for signs of wear or loose connections.Purpose: Ensures stable electrical performance and prevents potential electrical issues.

Verify Machine Calibration,Action: Perform a quick calibration check to ensure the machine's accuracy.Purpose: Ensures that the machine maintains precision and quality in its operations.

Lubricate Moving Parts,Action: Apply lubrication to moving parts as per the manufacturer's recommendations.Purpose: Reduces friction and wear, ensuring smooth operation.

Check Cooling System,Action: Verify that the cooling system is functioning properly.Purpose: Keeps the machine components at optimal temperatures and prevents overheating.

Inspect Filters and Pumps,Action: Check filters for clogs and ensure that pumps are operating correctly.Purpose: Ensures efficient filtration and fluid circulation.

Review Machine Settings,Action: Verify that machine settings (e.g., cutting parameters) are correctly configured for the day's tasks.Purpose: Ensures that the machine operates under optimal conditions for the current job.

Record Maintenance Activities,Action: Document daily maintenance activities and any issues encountered.Purpose: Provides a record for future reference and helps identify patterns or recurring problems.

Daily maintenance of the DK77 CNC Wire EDM Machine FZ involves checking and maintaining fluid levels, cleaning the work area, inspecting the wire feed system, and ensuring proper lubrication and calibration. Regular monitoring of electrical connections, filters, and cooling systems is also essential for optimal machine performance and longevity. Keeping detailed records of maintenance activities helps in managing the machine effectively and addressing any issues promptly.

English

English Español

Español